Assists movements with up to

25.5 kgf of auxiliary force.

Artificial muscle using air pressure,

so it adjusts to the movements of every person wearing the suit.

Easy for anyone,

anytime, anywhere.

Muscle Suit Every is

an assistive suit

that

works using air pressure.

Make life lighter

From lightening the load on your back at work

to helping with daily labor-intensive

activities. Muscle Suit Every is an assistive

suit created to help all people live healthy lifestyles.

Assists movements with up to

25.5 kgf of auxiliary force.

Artificial muscle using air pressure,

so it adjusts to the movements of every person wearing the suit.

No need for electricity !

lt works with air pressure

for an unlimited amount of time.

Simply fill it with air using the supplied pump and it is ready for use. Therefore it can be used anytime, anywhere, for an unlimited amount of time, easily. When the assistive power weakens, just add more air.

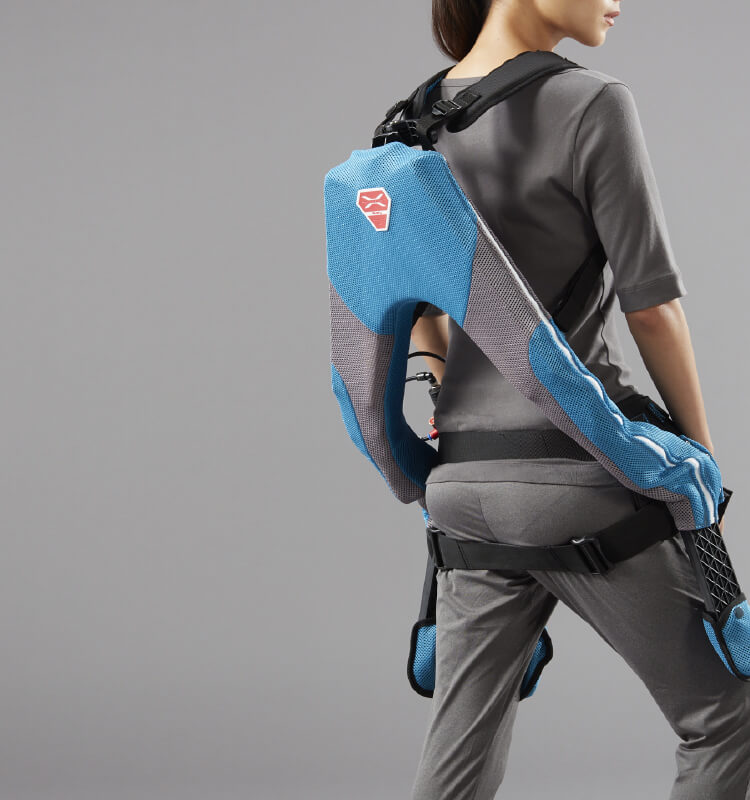

Product weight of 3.8 kg

It provides powerful assistance, and has been designed so that anyonce can use, including women, the elderly, and those concerned about their physical strength

Put it on in 10 seconds.

No expert skills are required.

Put it on like a backpack, tighten the belts, and you’re done.

No difficult maneuvering is required, so anyone can use it.

Made possible for families

to purchase.

Until now, assistive suits were a prohibitively expensive item.

Every underwent trials, not only from a technical perspective, but also in terms of price so that it is now a product that every family can afford.

Jobs outdoors or with water

are no problem.

No electricity required means you can wear it while working with water or outdoors without any problem. The product stands tough against water and dust but is gentle with people.

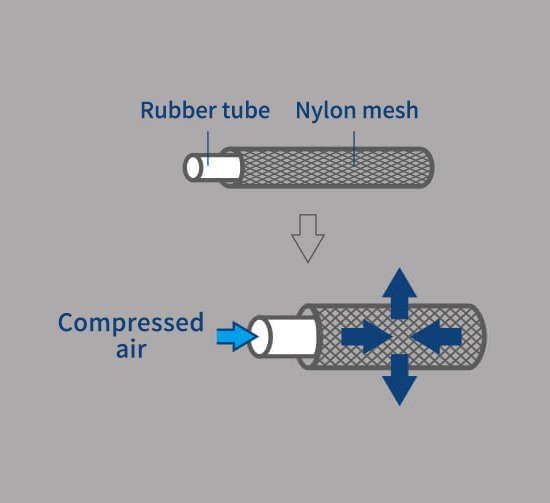

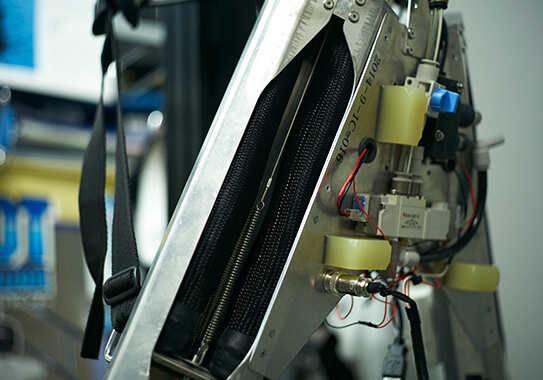

The Muscle Suit uses a McKibben-type artificial muscle as its driving force. The rubber tube is encased in a mesh made from polyester monofilament and both ends are secured with metal in this simple configuration.

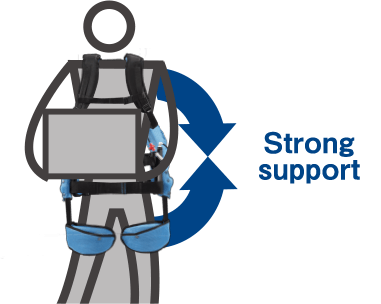

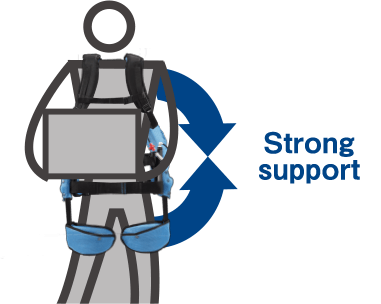

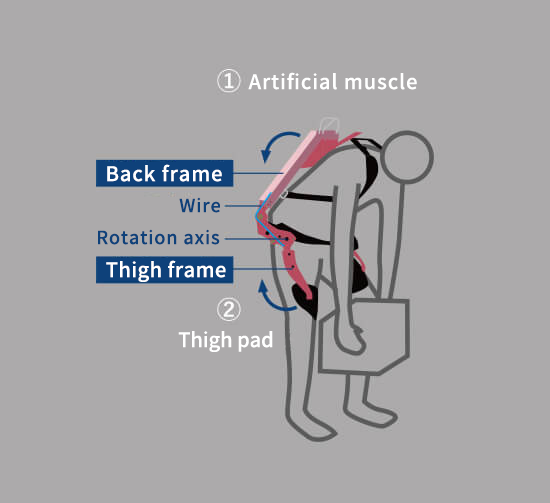

The Muscle Suit is made up of a back frame and thigh frame, and a rotation axis that connects the two. The upper end of the artificial muscle is affixed to the upper portion of the back frame, and the connected wire is affixed to the rotation axis at the lower end. With the compression of the artificial muscle, the wire is pulled and the back frame rotates around the rotation axis. As the thigh frame, which is affixed to the rotation axis, rotates in the opposite direction, the upper body is held upright using the thighs as the fulcrum.

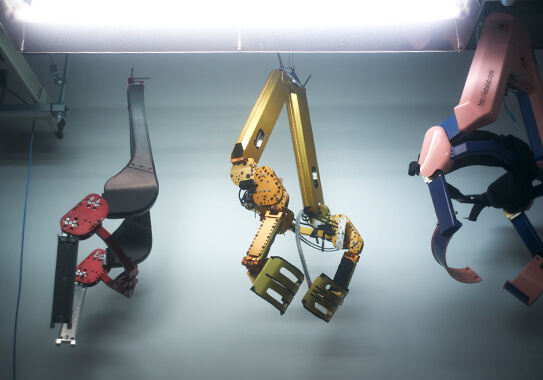

There are two types of Muscle Suit: tight-fit and soft-fit.

Soft-fit |

Tight-fit |

|

|---|---|---|

|

Features

|

There is some space between the thighs and the pads making it easier to walk with this type. (Assistance does not engage until the wearer is at a 35-degree angle, making it unsuitable for jobs that require only slight bending.) It is used for work involving manufacturing, distribution, construction, and other jobs that require heavy lifting and carrying.

|

This type provides assistance even when you are only bending a little. The pads are firmly affixed to the thigh giving a strong hold. (It is not suited to carrying heavy items for any distance.) It does not allow for a lot of movement, and is therefore suited to jobs that require maintaining a bending position in place.

|

|

Suited to

|

|

|

Types |

Soft fit /Tight fit |

|---|---|

Sizes:based on height(recommended) |

Small / Medium:150-165 cm, Medium/Large:160-185 cm |

Product weight |

3.8 kg *Not including cover |

Driving force |

Compressed air |

Actuator |

McKibben artificial muscle |

Compressed air supply method |

Manual air pump |

Assistive force |

25.5kgf(100Nm) |

Operating temperature |

-30℃~50℃ |

Dustproof/ Waterproof performance |

IP56 |

Product dimensions:H x Wx D |

Small/Medium:805mm/465mm/170mm Medium/Large:840mm/465mm/170mm |

Originally, I was interested in communication between robots and humans, and I began researching artificial intelligence in the 1990’s. I studied abroad at the University of Zurich in Switzerland, which was famous for artificial intelligence at the time, but as I continued my research, I didn’t want my career to end with conducting research and writing dissertations. I began to want to create something that would help the world as an engineer.

Around the time I returned to Japan from Switzerland in 1998, a Japanese-made robot that could walk on two legs became a hot topic of conversation worldwide. From a technological standpoint as well, it was amazing. But when I thought about whether it was really something that was useful, I decided that I wanted to make something that would solve the issue that troubled me most: one day becoming unable to stand on my own and being bedridden. Wondering if I could create a machine that could move and assist me in standing on my own was where it all started.

When you say “assistive suit,” most people will imagine something using an electric motor. However, my first priority was to create something strong and that moves smoothly. What can you wear on your body that is as light as possible, flexible, and strong? A pneumatic artificial muscle was the only answer. There was never any other choice in my mind. This seemed like the natural choice.

Honestly, this is something that didn’t exist anywhere in the world, so everything was a hurdle. We finally created something and took it out into the field where it immediately fell apart. There were more failures than successes. The reason I was still able to push forward was because I knew in my heart that this technology was absolutely necessary. One more reason is because someone who tried the suit on said to me, “Something like this is definitely needed.” I held fast to these two beliefs, and in 2013, the current lower back assistive-type suit was finally born.

Rather than an egocentric “I did it!” moment, it was when someone using it said, “This is so much easier!” that I first felt a sense of completion. However, there were still a mountain of issues, and people weren’t actually purchasing it. So I went back to ground zero in the development process, this time in the pursuit of lower cost and weight and better ease of use. The Muscle Suit Every finally born from that trial and error process succeeded in being half the weight of the original and 1/20 to 1/30 of the original price.

I basically have not changed from the person I was 20 years ago before the Muscle Suit came into existence, and I still want to find people who need help or problems that need solving and continue creating things that people feel are really necessary for as long as I can. However, I want to do it as quickly as possible and produce one new invention after the next. Being compared is the worst thing in the world, so I want to continue creating new things that can’t be compared to anything else.